简析德国大众汽车循环腐蚀试验标准PV1210_车身及附件腐蚀试验(中英文)

1 Scope应用范围

This Test Specification is used for corrosion testing in sample and standard-production tests conducted on completely painted bodies, body panels, assemblies and components with differing anti-corrosion coatings.

It serves to monitor and uate corrosion behavior or corrosion protection measures of these parts when exposed to static load.

本试验规范用于具有不同防腐涂层的完全油漆的车身、车身薄板、结构组件和 结构件的样品试验及批量试验中的腐蚀检测。

它用来检验和评价静态载荷下的防腐特性和防腐方法。

2 Designation标注

Corrosion resistance according to PV 1210 耐腐蚀性按PV 1210。

3 Test method试验方法

3.1 Principle原理

The test is an alternating cycle consisting of a combination of various climatic and/or corrosion loads.

A test cycle consists of

- 4 h salt spray fog test according to DIN 50021 -SS,

- 4 h aging in the DIN 50014-23/50-2 standard climate (including cooling-off phase),

- 16 hours humid aging at elevated temperature, climate according to DIN 50017- KK (40 ± 3) °C] 100% humidity.

After 5 cycles, a 2-day rest phase takes place in the DIN 50014-23/50-2 standard climate.

该试验是不同气候和/或腐蚀负荷的循环变化的组合。

一个试验循环包括

—4小时的盐雾试验,按DIN 50 021 - SS

—4小时标准气候DIN 50 014-23/50-2 (包括冷却阶段)下的存放

—16小时的湿热存放,气候按DIN50017-KK (40±3)℃ 100%空气湿度 ,5个循环后是2天在标准气候DIN 50 014-23/50-2下的静止状态。

Using this test method, corrosion behavior under static load resulting from salt, humidity and temperature is uated.

用这种试验方法通过盐,湿度和温度来评价静态负荷下的腐性特性。

Under these defined corrosion conditions, different anti-corrosion coatings can be comparatively assessed.

在这种特定的腐性条件下,可以对不同的防腐涂层进行对比评价。

A correlation with the corrosion mechanism in actual driving operation is not necessarily possible, as the types of vehicle damage and corrosion curves are complex and are not completely covered and reflected by the changing corrosion load.

A short interruption of the test for inspection purposes and/or the removal of test specimens is permitted. Interrupting the test by changing the test program is not permitted.

3.2 Test fixtures试验装置

Assemblies, components and test panels can also be tested in suitable single or alternate devices. The devices must comply with the specifications in DIN 50014, DIN 50017 and DIN 50021.

结构组件、结构件和板材试样的试验可以在适宜的单个或交变试验仪 器中进行。试验仪器应符合DIN 50014,DIN 50017和DIN 50021的规定。

3.3 Body test车身试验

Testing is performed according to Section 3.1. Examples are given in Section 3.6.

In order to carry out a specific uation of cavities, the body can be turned.

Before being initially brought into the salt spray test chamber, the body, mounted on the pivoting frame, is preconditioned in the DIN 50014-23/50-2 standard climate, and is then moved into the test chamber kept at a constant temperature.

验过程按3.1条。示例列举在3.6条中。

为了对空腔进行专门的评价,可以将车身旋转。

安装在旋转支架上的车身在首次进入

盐雾箱之前应在标准气候 DIN 50 014-23/50 -2下进行预处理,然后进入恒温处理过的试验箱中。

3.3.1 Salt spray phase盐雾阶段

During the test sequence with rotation, before each salt spray cycle, the body is turned about its lengthwise axis so that it is positioned as in the following sequence: 0°, 45°, 135°, 225° and 315°.

在旋转试验过程中,在每次盐雾循环前要将车身沿纵轴继续旋转,以便使其依次处于下述位置:0°; 45°; 135°; 225°和315°的位置。

3.3.2 Standard climate aging / humid aging at elevated temperature在标准气候下的存放/湿热存放

During the cooling-off phase and during humid aging at elevated temperature, the body is positioned horizontally.

在冷却阶段以及湿热存放期间,车身一直处于水平位置。

3.3.3 Repeating the test cycles重复试验循环

After humid aging at elevated temperature is completed according to Section 3.1, the body is immediately placed in the salt spray test chamber and turned 90° in a clockwise direction to 45°, 135°, 225° or 315°, according to the respective test cycle.

在结束3.1条的湿热存放后,紧接着将车身移到

盐雾箱中,并在可能的情况下

按各试验循环沿顺时针旋转90°,使其依次处于45°; 135°; 225°和315°的

位置。

3.3.4 Weekend aging周末存放

The rest phase entails aging in the DIN 50014-23/50-2 standard climate, with the body in a horizontal position and placed either in a suitable garage/hall or in the test chamber.

该静止状态是在车身处于水平位置的情况下在标准气候DIN 50014-23/50-2 下 在合适的地下室或大厅或试验间中进行的。

3.4 Component test结构件的试验

The required minimum for complete testing is 5 parts.

The components or their sections are tested in accordance with DIN EN ISO 7253 (see Section 4). Cavities must be exposed to the salt spray fog by cutting/opening of parts. If necessary,

unprotected trim edges must be covered before testing.

对于一次完整的检验至少需要5个零件。

按DIN 53167对结构件或其试样进行检验(见第4条)。

通 过 分 离 / 打 开 空 腔 使 得 盐 雾 能 够 进 入 空 腔 。 试 验 前 在 可 能 的 情 况 下 将 未 保 护 的 棱边遮蔽起来。

3.5 uation评价

After 15, 30, 60 and 90 cycles, the specimens are uated with regard to

- Type of corrosion (coating and/or base metal corrosion),

- Form of corrosion (surface or edge corrosion),

一 Time of appearance and development of corrosion,

as well as with regard to additional changes in the anti-corrosion coating such as loss of adhesion or blistering.

Organic coatings can be uated according to DIN EN ISO 4628-1, Table 3.

一般在15/30/60和90个循环后评价试样的

— 腐蚀种类(覆层和/或基金属腐蚀)。

— 腐性型式(平面腐性或边缘腐性)。

—腐蚀开始和腐性进展,

以及有关防腐涂层的其它变化,如刮刻线侵蚀,气泡等。

对有机涂层的评价可以使用DIN EN ISO 4628-1。

Signs of rust creep on painted sheets can be examined using a non-destructive thermographic method for quantitative uation of the development and spread of defects.

The test is concluded when corrosion grade Ri5 according to DIN EN ISO 4628-3 or corrosion perforations occur.

The following must be stated in the test report:

- Parts examined : e.g., painted sheets

- Corrosion protection measures: e.g., paint finish (coating thickness: 96 |im, measured

in the sheet center)

- Test:

为了检验油漆板的侵蚀现象,可以使用无破坏性的温度记录法来定量地评价缺陷位置的发展和扩大。

在出现根据DIN EN ISO 4628-3确定的Ri5锈蚀度或锈穿后,试验将被终止。

在试验记录中应说明:

— 检验的物件:如油漆板

— 防腐措施:如油漆(漆层厚度:在板的中央测量为96pm)

— 试验:开始/结束

- uation:

- Start of base metal corrosion: 一 Blistering:

Start/end

e.g., after 15 cycles: surface corrosion Ri 2 e.g., after 18 cycles: blistering grade 2 (S4)

- Adhesion loss: e.g., D = 3 mm

- End of test. e.g., after 30 cycles

- Notes / remarks

评价

— 基金属腐蚀开始,如15个循环后:平面腐蚀Ri2

一 气泡形成,如18个循环后:气泡程度2 (S4)

一 刮刻线侵蚀,如 D = 3mm

— 试验结束,如30个循环后

— 说明/注释

3.6 Examples for week cycle周循环示例

3.6.1 Example 1示例1

In manufacturing operations from 5:30 a.m. to 10:30 p.m., for one salt spray test chamber and four chambers for humid aging at elevated temperature (Table 1), change-over times max. 2x15 minutes per test cycle, throughput eight passenger car bodies.

Table1

| Bodies |

Salt spray fog test |

Cooling-off phase |

Humid aging at

elevated temperature |

Weekend aging |

|

| A/B |

6:00 a.m.-

10:00 a.m., Mo-Fr |

10:15 a.m.-

2:15 p.m., Mo-Fr |

2:30 p.m.-

5:45 a.m., Mo-Sa |

6:00 a.m.-

5:45 a.m., Sa-Mo |

|

| C/D |

10:00 a.m.-

2:00 p.m., Mo-Fr |

2:15 p.m.-

6:15 p.m., Mo-Fr |

6:30 p.m.-

9:45 a.m., Mo-Sa |

10:00 a.m.-

9:45 a.m., Sa-Mo |

|

| E/F |

2:00 p.m.-

6:00 p.m., Mo-Fr |

6:15 p.m.-

10:15 p.m., Mo-Fr |

10:30 p.m.-

1:45 p.m., Mo-Sa |

2:00 p.m.-

1:45 p.m., Sa-Mo |

|

| G/H |

6:00 p.m.-

10:00 p.m., Mo-Fr |

10:15 p.m.-

2:15 a.m., Mo-Fr |

2:30 a.m.-

5:45 p.m., Mo-Sa |

6:00 p.m.-

5:45 p.m., Sa-Mo |

|

3.6.2 Example 2示例1

In normal shift, for one salt spray test chamber and two chambers for humid aging at elevated temperature, throughput: four passenger-car bodies (Table 2)

Table2

| Bodies |

Salt spray fog test |

Cooling-off phase |

Humid aging at

elevated temperature |

Weekend aging |

|

| A/B |

8:00 a.m.-

12:00 p.m., Mo-Fr |

12:15 p.m.-

4:15 p.m., Mo-Fr |

4:30 p.m.-

7:45 a.m., Mo-Sa |

8:00 a.m.-

7:45 a.m., Sa-Mo |

|

| C/D |

12:30 p.m.-

4:30 p.m., Mo-Fr |

4:30 p.m.-

8:30 p.m., Mo-Fr |

8:30 p.m.-

11:45 a.m., Mo-Sa |

12:00 p.m.-

11:45 a.m., Sa-Mo |

|

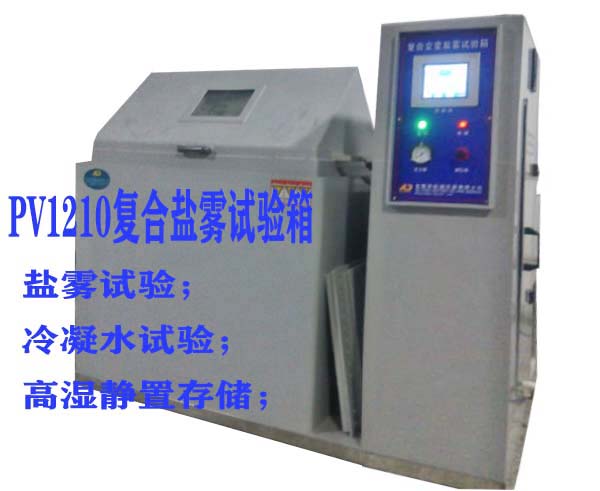

科迪仪器生产的多功能交变循环复合

盐雾箱可以完全实现上述德国大众PV1210测试标准的试验要求!

参考文献:

1、CETP 0000-L-467全球试验室加速循环腐蚀试验标准中文翻译版

2、浅析福特汽车CETP 0000-L-467测试标准的试验步骤及方法

3、简析通用汽车GMW 1487标准的试验流程及步骤

4、详细阐述德国DIN EN ISO11997-1循环腐蚀测试标准的试验方法和步骤

扫一扫,关注我们最新消息

扫一扫,关注我们最新消息